Concept of Value Chain

In high paced business climate, organizations are offering high quality product to gain long term competitiveness. In order to achieve desired results, the company has to match and then exceed their competitors, and even discover what the customers want and satisfy their expectations. Strategic analysis helps the company focus its plan and hence achieve a competitive advantage. A strategic management accounting technique used to measure the importance of the customer's perceived value is value chain analysis. Through evaluating the strategic advantages and disadvantages of the company's activities and value-creating processes in the market place, value chain analysis is needed to evaluate the company's competitive advantages.

Value chain analysis proposes the systematic view of organizations composed of stages in transformation process with inputs and outputs to each of the distinct stages (Satya Sekhar, 2009). Value chain analysis is dependent on the basic fiscal principle of advantage. Companies are best served by operating in sectors where they have a relative productive advantage compared to their competitors. Concurrently, companies should ask themselves where they can deliver the best value to their customers.

Michael Porter (1995) introduced the notion of Value chain in his book "Competitive Advantage: Creating and Sustaining Superior Performance". The concept of value added, in the form of the value chain, can be utilized to develop an organisation's sustainable competitive advantage in the business field of the 21st Century. All organisations consist of activities that link together to develop the value of the business, and together these activities form the organisation's value chain. Such activities may include purchasing activities, manufacturing the products, distribution and marketing of the company's products and activities (Lynch, 2003). The value chain framework has been used as a powerful analysis tool for the strategic planning of an organisation for nearly two decades. The aim of the value chain framework is to maximise value creation while minimising costs. Porter described as the price that customer is prepared to pay for an offering. Profit is the difference between this value and total cost to the enterprise providing that offering (Satya Sekhar, 2009). He outlines the value chain as the internal processes through which the company designs, produces, sells, delivers and supports its product. Cost is no longer treated as an expense that goes to the profit and loss account, but it is treated as value that accumulates to company wealth as shown in balance sheet.

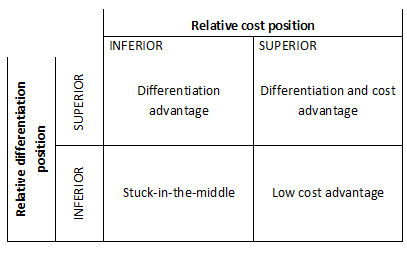

Porter indicates that "a company's value chain and the way it performs individual activities are a reflection of its history, its strategy, its approach of implementing its strategy, and the underlying economics of the activities themselves." From fundamental perspective, the value chain framework is an approach for breaking down the sequence of business functions into the strategically relevant activities through which utility is added to products and services. Value chain analysis is undertaken in order to understand the behaviour of costs and the sources of differentiation (Shank and Govindarajan, 1993). Porter (1980) argued that a business can develop a supportable competitive advantage based on cost, differentiation, or both.

Source: Shank and Govindarajan (1993)

To perform a value chain analysis, the company begins by recognizing each part of its production process and identifying where steps can be eliminated or improvements can be made. These improvements can result in either cost savings or improved productive capacity. The end result is that customers derive the most benefit from the product for the cheapest cost, which improves the company's bottom line in the long run.

The notion of the value chain is based on the process view of organisations, the idea of seeing a manufacturing (or service) organisation as a system, made up of subsystems each with inputs, transformation processes and outputs. Inputs, transformation processes, and outputs involve the acquisition and consumption of resources - money, labour, materials, equipment, buildings, land, administration and management. How value chain activities are carried out determines costs and affects profits.

The main purpose of value chain is to measure the value delivered and profit contributed by each link of chain. A value chain is linked set of value creating activities beginning with basic raw material coming from suppliers, moving onto the series of value added activities involved in producing and marketing a product or services and ending with distributors getting the final goods into the hands of ultimate consumers (Satya Sekhar, 2009).

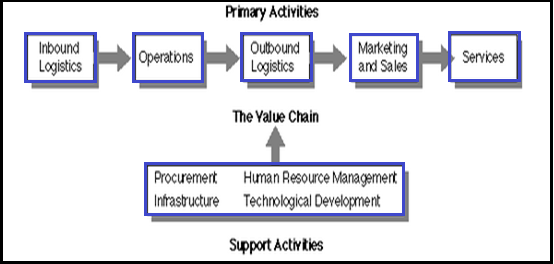

Most organisations engage in numerous activities in the process of converting inputs to outputs. These activities can be classified generally as either primary or support activities that all businesses must undertake in some form.

Porter (1985) grouped business activities under two categories that include primary product line activities and support activities. Primary activities are the processes directly involved in transforming materials into finished goods, then goods delivery and aftersales services to goods sales. They basically include:

- Materials intake, specification check, handling and warehousing

- Materials and components processing into finished goods

- Order processing and distribution

- Communication, pricing and decision-making by management, and

- Installation, repair and parts replacement.

In detail, Porter's value chain model (1985) described five value generating primary activities (Satya Sekhar, 2009).

These primary activities are:

Inbound Logistics - involve relationships with suppliers and include all the activities required to receive, store, and disseminate inputs. These activities are associated with receiving, storing, disseminating inputs to the product such as material handling, warehousing, inventory control, vehicle scheduling and return to suppliers.

Operations: These are all the activities required to transform inputs into outputs (products and services). For example machining, packing assembly, equipment maintenance, testing, printing and facility operations.

Outbound Logistics: These include all the activities required to collect, store, and distribute the output. Such as finished goods warehousing, material handling, delivering vehicle operation, order processing and scheduling.

Marketing and Sales: Activities inform buyers about products and services, induce buyers to purchase them, and facilitate their purchase. Such as Advertising, promotion, sales force quoting, channel selection, channel relation and pricing.

Service - includes all the activities required to keep the product or service working effectively for the buyer after it is sold and delivered. Such as installation, repair, training, parts supply and product adjustment.

Support activities are the processes and actions to facilitate the primary product line activities. They are the company's staff functions. Secondary activities of value chain are as follows:

Procurement - is the acquisition of inputs, or resources, for the firm.

Human Resource management: This consists of all activities involved in recruiting, hiring, training, developing, compensating and (if necessary) dismissing or laying off personnel.

Technological Development: It pertains to the equipment, hardware, software, procedures and technical knowledge brought to bear in the firm's transformation of inputs into outputs.

Company Infrastructure – This serves the company's needs and ties its various parts together, it consists of functions or departments such as accounting, legal, finance, planning, public affairs, government relations, quality assurance and general management.

Porter's Value Chain

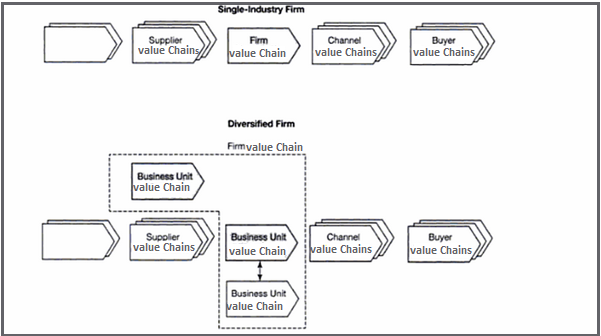

Value chain analysis is a practise that yields value enhancement. There are two components of value chain analysis: the industry value chain and the company's internal value chain. The industry value chain includes all of the value-creating activities within the whole industry, beginning with the basic raw material and ending with the after-sales service of the product sold. The internal value chain of a company comprises of all the value creating activities of that specific company.

To gather information for Value Chain Analysis, Analysts can explore various sources to find information necessary for conducting the value chain analysis. Up to three years of annual reports of the company can be analysed to see how the costing of the activities are changing over the period and whether they are in unison with the competitive strategy of the firm. These annual reports of the company can be compared to the annual reports of the major competitors in order to see how competitive strategies differ between the companies, along with finding the difference in the contribution of activities to the company's profitability. In order to gain knowledge about the core competence of the company, analysts can look at the company and competitor websites. SWOT analysis of the companies done by companies like Data monitor can help the analyst to understand the key strengths and weaknesses of the company and how the firm differs from its competitors. Furthermore, journal articles, trade publications and magazines are useful sources of information to identify how value is created in the particular industry in which the company operates and which activities play a key role in the generation of that value.

Implementation of Value Chain Analysis

There is a three-stage process to perform value chain analysis. It delivers value to customers and reviews all processes to maximize product value.

- Activity Analysis: Ascertain the activities that contribute to the processing of the product or service.

- Value Analysis: Identify the items and/or services that customers value in the way one conducts each activity, and then calculate the changes based on relevant structural and/or executional cost drivers.

- Evaluation and Planning: Decide what changes to make and determine how to conduct the plan.

The value chain approach for assessing competitive advantage:Most corporations describe their mission as one of creating products or services. For these organizations, the products or services generated are more important than any single step within their value chain. In contrast, other companies are fully aware of the strategic importance of individual activities within their value chain. They succeed by concentrating on the particular activities that allow them to capture maximum value for their customers and themselves. These firms use the value chain approach to better understand which segments, distribution channels, price points, product differentiation, selling propositions and value chain configurations will yield them the greatest competitive advantage. The way that the value chain approach supports organizations evaluate competitive advantage is through numerous analysis:

- Internal cost analysis: To determine the sources of profitability and the relative cost positions of internal value-creating processes.

- Internal differentiation analysis: To understand the sources of differentiation (including the cost) within internal value-creating processes.

- Vertical linkage analysis: To understand the relationships and associated costs among external suppliers and customers in order to maximize the value delivered to customers and to minimize cost.

Basically, companies start by focusing on their internal operations and gradually widen their focus to consider their competitive position within their industry. The value chain approach to appraise competitive advantage is vital part of the strategic planning process. Value chain analysis is a continuous process of gathering, evaluating and communicating information for business decision-making. By stimulating strategic thinking, the analysis assists managers envision of the company's future and implement decisions to attain competitive advantage. Organizations adopt the value chain approach to recognize sources of profitability and to understand the cost of their internal processes or activities (David Barnes, 2001). The main steps of internal cost analysis are:

- Identify the firm's value-creating processes.

- Determine the portion of the total cost of the product or service attributable to each value creating process.

- Identify the cost drivers for each process.

- Identify the links between processes, and

- Evaluate the opportunities for achieving relative cost advantage.

A firm must de-emphasize its functional structure to identify its value-creating processes. Most of large businesses still organize themselves as cost, revenue, profit and investment centres. These and other organizational sub-units, such as departments, functions, divisions or separate companies that are normally used for control purposes are not very useful for identifying value creating processes. Adopting a process perspective requires a horizontal view of the organization, beginning with product inputs and ending with outputs and customers. Organizations also adopt the tool of value chain approach to identify opportunities for creating and sustaining superior differentiation. In this situation, the primary focus is on the customer's perceived value of the products and services. It can be said that firm's value chain is embedded in large stream of activities. Suppliers have value chain that create and deliver the purchased input used in firm's chain. Suppliers not only deliver the product but also can influence a performance of firm in numerous ways. Additionally, many products pass through value chains of channels on their way to the buyer. Channels perform additional activities that affect the buyer and influence firm's own activity. A firm product eventually become part of buyer's value chain. The ultimate basis for differentiation is firm and its product role in the buyer's value chain which determine buyer's needs. Achieving competitive advantage depends on to understand value chain of firm and how firm fits to its overall value system (David Barnes, 2001).

Value Chain And Competitive Advantage (David Barnes, 2001)

Benefits of Value Chain Analysis

The value chain links up a series of value creating activities from supplier to customer. The intent of value chain analysis is to perform value chain activities more efficiently and at a lower cost than rivals. The focus is the chain from the customer's viewpoint. Value chain analysis extends from materials input, work-in-process and finished goods manufactured to other primary activities as after-sales services, as well as support activities as procurement, technology, human resources management and company infrastructure. Value chain analysis is a framework that can provide a number of benefits to the management of online learning organizations. This analysis can support managers to identify linkages between value activities within the organization, and to think in terms of process rather than function or department. Through analysis of the value system, managers can identify potentials for strategic alliances with various actors in the industry value system. Identification of cost drivers and linkage with value chain activities help managers to focus on cost reduction and on finding ways to optimize returns throughout the value chain. As well, value chain analysis helps managers to understand cost management problems. Failure to see the impact of a decision on the overall value chain will result in missed opportunities.

Drawbacks of Value Chain Analysis

Value chain analysis is considered as a new strategic management accounting device and has several operational demerits:

- Availability of data: Company data about revenues, costs, and assets used for value-chain analysis are obtained from financial information in a single period. Multiple-period data for long-term strategic decision-making, changes in cost structures, capital investments and market prices may not be immediately available.

- Ascertainment of revenues, costs and assets: Identification of appropriate revenues, costs, and assets for each value chain activity is quite difficult. As there is no scientific approach, and most work is done through trial-and-error and experimentation methods.

- Identification of cost drivers: Isolation of cost drivers for value-creating activities, identification of value chain linkages across activities, and computation of supplier and customer profit margins present major constraints.

- Identification of stages: Identification of stages in an industry's value chain is affected by the ability to locate at least one company department that participates in a specific stage. Breaking down a value stage into two or more stages is necessary for diagnosing abilities at various stages.

- Opposition from employees: Value chain analysis involving strategic partners outside the company is still a new concept and is not easily understood by all employees. It may face resistance from front line staff as well as managers.

The use of value chain analysis facilitates the strategic management of an organization. Michael Porter's influential work in strategic management elucidates the fundamentals of how organizations compete.

To summarize, value chain process integrates external and internal data, applies appropriate cost drivers for all major value-creating processes, exploits linkages throughout the value chain and offers continuous monitoring of a company's strategic competitive advantage. It involves the inputs of other strategic partners, such as material suppliers, finished goods wholesalers, and final customers. The main objective is to conduct value chain activities more efficiently, and ultimately surpass industrial competitors. Value chain analysis can support companies to determine which type of competitive advantage to follow, and how to pursue it. Many academicians stated that value chain is an effectual technique for organizational appraisal as it helps in providing clarity about the areas of strengths and weaknesses. It is a popular framework to analyse and develop competitive advantage.