Supply Chain Management

Supply chains are vital process in managing activities of organization. It incorporates the companies and the business activities that are required to design, make, deliver, and use a product or service. In international business climate, supply chain strategies are implemented by most of the companies. The main motivation to implement supply chain policies is aggressive competitive pressure, and organization visualize that through effective supply chains, they can flourish in marketplace. Oliver and Webber stated that the supply chain is visualized as a distinct unit and no other arenas of responsibility like purchasing, engineering, and distribution (1982). Businesses rely on their supply chains in order to provide them with what they need to survive and flourish. Every business fits into one or more supply chains and has an important role to play in each of them. The practice of supply chain management is guided by fundamental management concepts that are developed from earlier time.

The term "supply chain management" arose in the late 1980s and came into extensive use in the decade of 1990. Supply Chain Management (SCM) and Execution (SCE) are the interactive and collective processes and tools that influence strategic relationships within the supply chain for the sharing of confidential and mission critical sales, forecasting, planning, purchasing and replenishment data with the crucial objective of maximizing efficiencies, reducing costs and increasing profits by proactively insuring that the right product is delivered to the right place at the right time.

Theoretical perspective: The phrase supply chain management was originally introduced by consultants in the decade of 1980's and consequently has become extensively used. Since the early 1990's, researchers have attempted to describe supply chain management. Bechtel and Jayaram provided an extensive retrospective review of the literature and research on supply chain management. They identified general schools of thought, and the major contributions and fundamental assumptions of supply chain management that must be challenged in the future. In recent time, numerous practitioners, consultants and academics visualized supply chain management as not appreciably different from the modern understanding of logistics management, as explained by the Council of Logistics Management. Supply chain management was viewed as logistics outside the firm to include customers and suppliers. The understanding of supply chain management has been re-conceptualized from integrating logistics across the supply chain to integrating and managing main business processes across the supply chain.

Current description of supply chain management is as follows:

"Logistics is that part of the supply chain process that plans, implements, and controls the efficient, effective flow and storage of goods, services, and related information from the point-of-origin to the point-of-consumption in order to meet customers' requirements".13

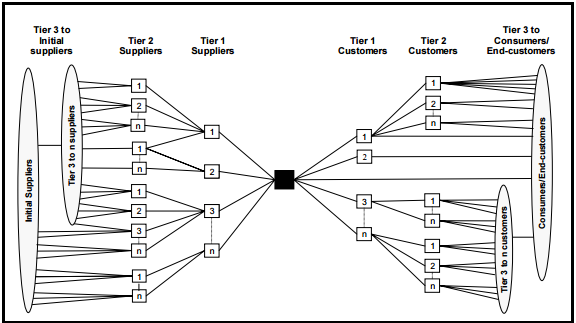

Lambert, Stock, and Ellram described that a supply chain is the alignment of firms that bring products or services to market." According to Chopra and Meindl, A supply chain consists of all stages involved, directly or indirectly, in fulfilling a customer request. The supply chain not only includes the manufacturer and suppliers, but also transporters, warehouses, retailers, and customers themselves. Other theorists, Ganeshan and Harrison stated that a supply chain is a network of facilities and distribution options that performs the functions of procurement of materials, transformation of these materials into intermediate and finished products, and the distribution of these finished products to customers."

Supply chain network structure (Source: Douglas M. Lambert, Martha C. Cooper, and Janus D. Pagh, 1998)

The basic supply chain should be incorporated to manage a multifaceted flow of information, both between and within enterprises. The major challenge is to assimilate this information and make it accessible where, when and how needed. For most profitable supply chains, value will be strongly correlated with supply chain success, the difference between the revenue generated from the customer and the overall cost across the supply chain (Chopra, Sunil and Peter Meind, 2004).

Effective supply chain management needs concurrent improvements in both customer service levels and the internal operating efficiencies of the organizations in the supply chain. Customer service at its most elementary level means consistently high order fill rates, high on-time delivery rates, and a very low rate of products returned by customers for whatever reason. Internal efficiency for organizations in a supply chain means that these organizations get an attractive rate of return on their investments in inventory and other assets and that they find ways to lower their operating and sales expenses. There is a fundamental pattern to the practice of supply chain management. Each supply chain has its own exclusive set of market demands and operating challenges.

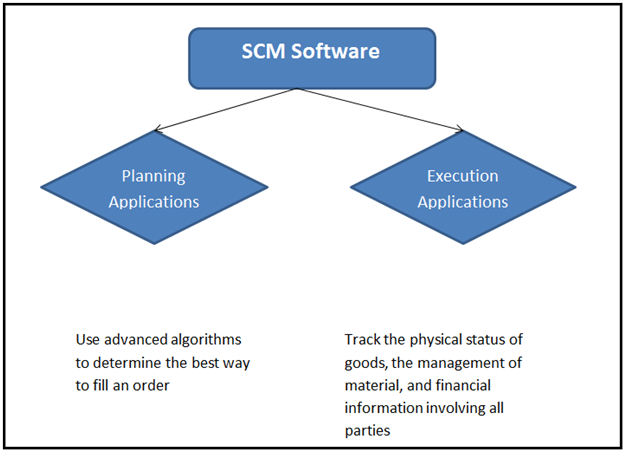

The ultimate goal of supply chain is to decrease the inventory with the assumption that products are available whenever required. As a solution of successful supply chain management, sophisticated software system with web interfaces are competing with web application service providers who promise to offer part or all of for companies who rent their services.

Figure:

Supply chain management must be observed as a critical element of business strategy, delivering improved productivity through increased efficiencies and dealer management strategy requires the devoted efforts of a talented team. There is a great challenge with managers who manage within the supply chain, in having the ability to maintain focus on strategy despite the barrage of transactional issues they are engrossed in.

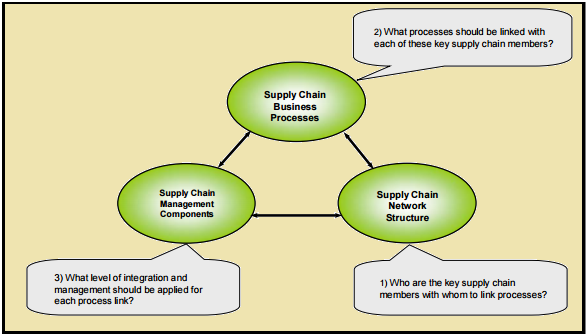

The conceptual framework highlights the inter-related nature of SCM and the need to proceed through several steps to design and successfully manage a supply chain. The supply chain management framework consists of three closely inter-related elements: the supply chain network structure, the supply chain business processes, and the supply chain management components.

Figure: Supply Chain Management Framework: Elements and Key Decisions (Source: Douglas M. Lambert, Martha C. Cooper and Janus D. Pagh, 1998)

There are six elements of supply chain strategy, which, if utilized collectively and managed carefully, will deliver significant value across the organization.

- Leverage: In spite of the size and profits of an organization, decrease and management of spending while continuously improving upon service levels is a major benefit of managing leverage. Leverage has characteristically been applied based on historical usage trends and market expectations. However, the more dominant way to initiate leverage is through solid and supported predictions of future growth potential.

- Communication: In any business, main element is the support provided by external resources, be they service providers or product and component suppliers. Obtaining value from these external resources to fulfil evolving company objectives requires an effectual communication strategy.

- Efficiency: Process and operating efficiency is basic constituent of flourishing organization and the supply chain has impact on this efficiency either directly or indirectly. For instance, enhancements in production efficiency need increased volumes of supply of both components and maintenance equipment; improvements in process efficiency require increases in volume and timeliness of support from external suppliers and contractors; increased speed to market requires the support of accurate and timely freight management. Developing suitable strategy to support organizational efficiency is main factor to accomplish objectives and improving efficiencies.

- Innovation: In order to manage routine operations, while initiating innovation are not commonly exclusive events. To create innovation in any organization, it needs significant input and support from external suppliers and service partners, both of whom must be willing to provide insight and support and take potential risks in pursing innovative solutions. Innovative organizations like Apple would not have succeeded if it were not for the engagement and support of their suppliers such as Samsung.

- Risk Management: Those organizations that represent and support company operations externally present the more unmanageable risk to an organization. E xternal risk is also the most overlooked risk as it is not as widespread or visible as other internal risk factors. Supply chain management is the function most in-tune with external support groups, and is able to recognize potential risks as well as alleviating solutions to protect the organization's interest. Developing an effective risk management strategy requires the support and input from main Supply Chain specialists.

- Continuous Improvement: Topmost organizations involve continuously in improving their performance. Considering that most improvements have an impact on external support groups either directly or indirectly. Supply chain management is the tool to recognize and manage improvement opportunities. Continued modernisation to Apple software for iPhones, iTunes, and other products are the outcome of supplier involvement in constant improvement that results in the quick resolution of instant for predicted challenges. This creates greater customer satisfaction and brand faithfulness. Continuous improvement also offers numerous opportunities to decrease cost, and supply chain management is the most proficient and knowledgeable process relative to reducing cost through internal and external efficacy.

Companies in any supply chain must make decisions independently and jointly regarding their actions in five areas:

- Production: This function includes the creation of master production schedules that take into account plant capacities, workload balancing, quality control, and equipment maintenance.

- Inventory: The main purpose of inventory is to act as a cushion against ambiguity in the supply chain. However, holding inventory can be luxurious.

- Location: Managers have to decide where facilities for production should and inventory storage is to be located, the most cost efficient locations for production and for storage of inventory. Once these decisions are made, they determine the possible ways available for product to flow through for delivery to the end-users.

- Transportation: Mangers must also take decision about how should inventory be shipped from one supply chain location to another.

- Information: It is a crucial decision for experts that how much data should be collected and how much information should be shared. Timely and precise information holds the promise of better coordination and better decision making. With relevant information, personnel can make good decisions about production and how much, and about where to locate inventory and transportation.

Effective and reliable supply chain solution engage in five major steps.

- Plan: The first stage, planning, is self-explanatory. Company managers develop strategies to manage resources for timely product delivery. Metrics should be developed to monitor progress and compliance.

- Develop: Second step is to select suppliers. Managers are responsible for developing a system for pricing, delivery and payment.

- Make: The third phase is manufacturing. During this step, the manager schedules activities necessary for production, testing, packaging and preparation for delivery of goods or services to customers.

- Delivery: Fourth stage is delivery, or logistics of supply chain management. Managers coordinate order receipts, develop a network of warehouses and choose their carriers.

- Return: There is the defect and excess stage, which is likely the most difficult to handle effectively. In this stage, managers need to review their system of supporting customers who have problems with product delivery.

Benefits of supply chain management: There are several benefits of supply chain management. Effective supply chain management achieves more precise information, along with the ability to carry out better sales forecasting. Other benefits include developing strong partnerships and supplier networks, balancing out supply and demand, improving business plans and working strategies, predicting transportation requirements, planning daily operations of the company, creating streamlined inventory management and removing irrelevant elements.

While all organizations have supply chain processes of varying degrees, it is important to understand, identify and implement each stage with careful consideration. Variables, including the size of the organization and the type of product manufactured affect supply chain management components.

To summarize, a supply chain comprises of all the companies involved in the design, production, and delivery of a product to market. Supply chain management is the synchronisation of production, inventory, location, and transportation among the participants in a supply chain to accomplish the best mix of receptiveness and effectiveness for the market being served. The objective of supply chain management is to escalate sales of goods and services while reducing both inventory and operating expenses.